Manufacturers & Exporters of Flanges, Pipe Fittings & Tube Fittings

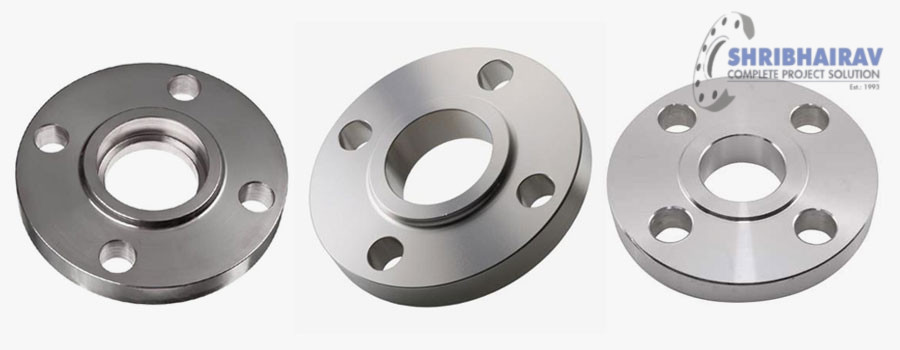

Slip-on (SO) flanges are a type of flange characterized by a flat face on the sealing surface. They are commonly used in low-pressure applications. The term "slip-on" comes from their easy installation: they simply slip onto the end of a pipe or fitting and are then welded in place. Their bored inner diameter matches the pipe's outer diameter, ensuring a smooth flow of fluids or gases.

This article explores the fundamentals of SO flanges, including their working principles, advantages, and various types.

SO flanges provide a secure and leak-resistant connection between pipes or fittings in a piping system. The process involves:

SO flanges offer several advantages, making them a popular choice in various piping systems:

Standard (or raised-face) SO flanges have a raised face on the sealing surface. This raised face provides a platform for the gasket, ensuring a reliable seal between the flange and the adjoining pipe or fitting. They are well-suited for low-pressure applications where the bolt-tightening force can adequately compress the gasket.

Lap joint SO flanges have a flat face with a separate backing flange. The backing flange slides over the pipe end and aligns with the lap joint stub end, which is then attached to the pipe. This design allows for rotational movement, providing flexibility in alignment during installation or maintenance. They are commonly used in systems requiring frequent dismantling or in applications with thermal expansion or contraction.

Need assistance choosing the right Flange for your system? Shribhairav Metal Corporation provides expert support and customized quotes.

📞 Call us: +91 22-6636-2333

📧 Email us: sales@shribhairavforge.com